Fiber Laser Welding Machine Alibaba

After-sales service can be contacted by phone, email or via their social media profiles.

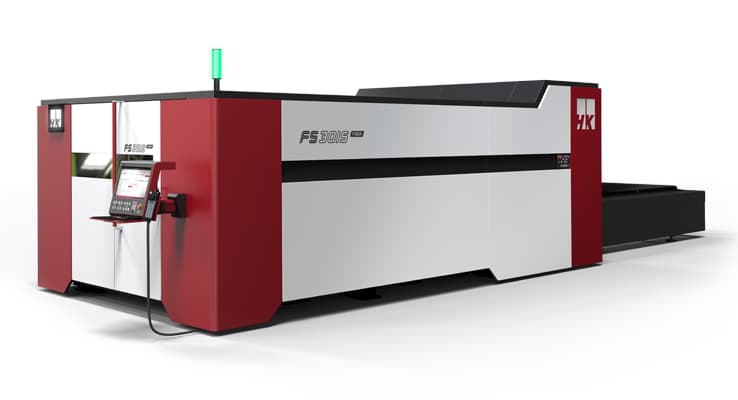

Cheap 4x8 laser stainless steel cutting machine with 1000 watt fiber laser generator is designed for cutting thin metals less than 2mm aluminum, 3mm stainless steel, 4mm carbon steel, copper, and brass, now the affordable 4x8 stainless steel laser cutter for sale at a low price.